In modern manufacturing, small details make a big difference. Whether it’s an aerospace turbine blade, an automotive engine part, or a medical implant, even a fraction of a millimetre can determine whether a component functions perfectly or fails altogether. This is where tolerances and precision in CNC manufacturing come into play.

CNC (Computer Numerical Control) machining is known for its ability to produce highly accurate and repeatable parts. However, achieving true precision isn’t just about using advanced machines — it’s about understanding and controlling tolerances.

This article explains what tolerances mean, why they matter, how they are measured, and how precision is maintained in CNC manufacturing.

What Are Tolerances in CNC Manufacturing?

In simple terms, a tolerance defines the permissible variation in a part’s dimension. No machining process can produce parts that are perfectly exact to a design’s nominal measurement — slight differences always occur due to tool wear, thermal expansion, machine vibration, or material properties.

A tolerance tells the machinist how much deviation is acceptable without affecting the part’s performance or assembly.

For example:

If a design specifies a shaft with a diameter of 10.00 mm ±0.02 mm, that means the final part can measure anywhere between 9.98 mm and 10.02 mm and still be considered within tolerance.

Tighter tolerances mean less variation — and higher accuracy — but also higher production costs and time. Therefore, the key is finding the right balance between functional requirements and manufacturability.

Why Tolerances Matter

Tolerances are vital because they ensure that manufactured parts fit, function, and perform as intended when assembled or operated. In many cases, multiple components must work together within a system — and even minor inconsistencies can cause misalignment, friction, or mechanical failure.

Here are some key reasons tolerances matter:

- Interchangeability:

When multiple identical parts are produced, tolerances ensure that any part can fit into an assembly without the need for manual adjustments. - Functionality:

Correct tolerances maintain mechanical relationships between moving parts, ensuring smooth operation and efficiency. - Quality Control:

Tolerances provide measurable standards to inspect and verify part quality. - Cost Management:

Overly tight tolerances increase machining time, tool wear, and inspection requirements. Setting realistic tolerances helps reduce unnecessary costs. - Safety and Reliability:

In critical applications — like aerospace or medical devices — incorrect tolerances can lead to system failure. Maintaining precision is vital to safety.

Types of Tolerances

In CNC manufacturing, tolerances can be classified into several types depending on the feature being measured.

1. Dimensional Tolerances

These control the allowable variation in a part’s overall size — such as the diameter of a hole, the thickness of a plate, or the length of a shaft.

Example: 20.00 mm ± 0.05 mm

2. Geometric Tolerances

These define how a feature’s shape, orientation, or position can vary relative to other features. Geometric Dimensioning and Tolerancing (GD&T) standards are used for this purpose.

Common types include:

- Flatness: Ensures a surface lies within a specified flat plane.

- Roundness: Controls the circularity of cylindrical parts.

- Perpendicularity: Maintains a 90° relationship between surfaces.

- Parallelism: Keeps two surfaces or features evenly spaced.

- Concentricity: Ensures cylindrical features share the same axis.

3. Surface Finish Tolerances

Surface texture affects how parts interact, especially in assemblies involving seals or sliding components. Tolerances for surface roughness are measured in micrometres (µm) and depend on the function of the part.

Understanding Precision in CNC Manufacturing

Precision refers to the consistency and repeatability of measurements — the ability of a CNC machine to produce parts that match each other closely.

A CNC machine can be precise but not accurate if it repeats the same wrong measurement every time. True quality requires both precision (repeatability) and accuracy (closeness to the target dimension).

Precision in CNC manufacturing depends on several key factors:

- Machine Quality and Calibration

High-quality CNC machines are built with rigid frames, advanced control systems, and precise spindles. Regular calibration ensures that all axes move accurately and consistently. - Tool Condition

Cutting tools wear over time, which can affect size, surface finish, and geometry. Monitoring and replacing worn tools is crucial to maintaining precision. - Material Properties

Materials expand or contract with temperature changes. Machinists must account for thermal effects, especially with metals that have higher thermal expansion rates. - Environmental Stability

Temperature, humidity, and vibration in the workshop can influence measurements. Controlled environments ensure consistent machining results. - Operator Skill and Programming

Even with automated machines, skilled programmers and machinists play a key role. Correct G-code, feed rates, and cutting speeds all affect the final tolerance.

Also, check out the complete guide to custom apparel manufacturing

How Tolerances Are Measured and Verified

Precision is meaningless without verification. In CNC manufacturing, tolerances are checked using various inspection tools and techniques.

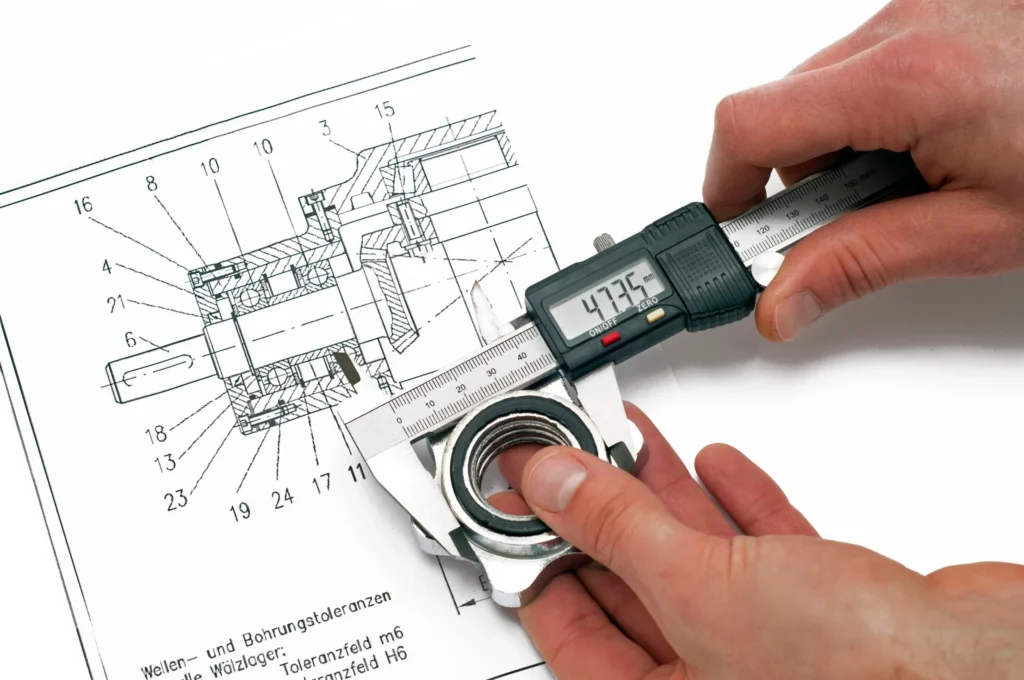

1. Vernier Calipers and Micrometres

These handheld instruments are used for basic measurements of dimensions like length, diameter, and thickness, typically accurate to within 0.01 mm.

2. Coordinate Measuring Machines (CMMs)

CMMs use a mechanical probe, laser, or optical sensor to measure the geometry of parts in 3D. They can inspect complex features and produce detailed reports of dimensional accuracy.

3. Optical and Laser Scanners

For non-contact measurement, laser scanning systems capture surface data and generate digital 3D models to compare against the CAD design.

4. Surface Roughness Testers

These instruments assess the texture of machined surfaces, providing readings in Ra (average roughness) values.

Regular inspection throughout the production process — not just after completion — helps detect deviations early and reduces scrap or rework.

Balancing Tolerance and Cost

One of the biggest challenges in CNC manufacturing is determining how tight a tolerance really needs to be. Tighter tolerances require more time, specialised tooling, slower cutting speeds, and more inspections — all of which raise costs.

The goal is to specify tolerances that are as loose as possible but as tight as necessary for the part’s function. For example:

- A decorative panel may only require ± 0.5 mm tolerance.

- A bearing housing or gear shaft may require ± 0.01 mm or better.

Understanding the purpose of the part and its role in the overall assembly helps engineers set realistic, cost-effective tolerances.

Standards and Best Practices

Tolerances in CNC manufacturing are governed by international standards that ensure consistency and compatibility across industries. The most common include:

- ISO 2768: General tolerances for linear and angular dimensions.

- ASME Y14.5: The primary standard for GD&T in North America.

- DIN ISO 1101: European equivalent for geometric tolerancing.

Following these standards ensures that drawings and manufacturing instructions are clearly understood worldwide.

Best practices for maintaining precision:

- Calibrate machines regularly.

- Inspect cutting tools before and after production runs.

- Use stable fixturing to minimise vibration.

- Apply consistent temperature control in the machining area.

- Document inspection data to monitor process capability (Cp, Cpk values).

The Future of Precision in CNC Manufacturing

As technology advances, CNC machining is becoming even more precise and data-driven. New systems incorporate:

- AI-assisted monitoring that predicts tool wear.

- Digital twin simulations to test setups virtually.

- Nano-scale machining for industries like electronics and optics.

- Real-time feedback sensors that correct deviations automatically.

These innovations are pushing the limits of what’s physically possible, achieving tolerances measured in microns or even nanometres.

Conclusion

Tolerances and precision are the foundation of quality in CNC manufacturing. They define how closely a machined part matches its intended design — and ensure that complex assemblies function reliably, safely, and efficiently.

By understanding the relationship between tolerances, material behaviour, tooling, and inspection methods, manufacturers can achieve the perfect balance between accuracy, cost, and performance.

In the world of modern CNC machining, precision isn’t just a technical requirement — it’s the standard that drives progress, reliability, and innovation across every industry.